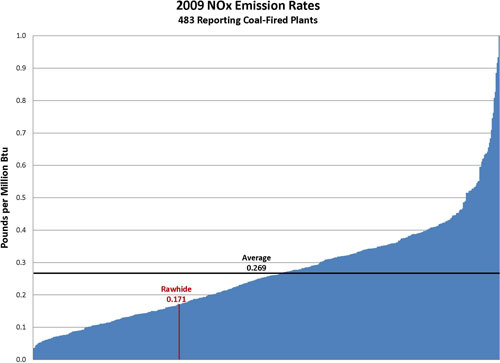

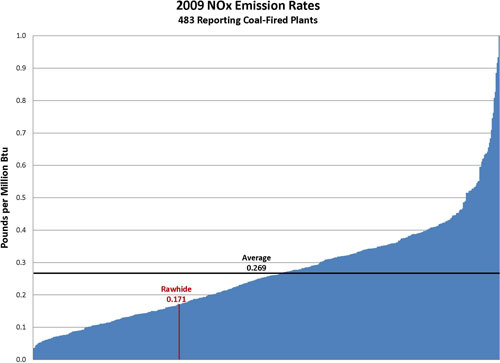

Nitrogen oxides

(NOx) are air pollutants produced during coal combustion. The rate

of NOx formation depends on combustion temperature

and

available oxygen and can rise significantly if not properly controlled.

Consequently, combustion control techniques can influence and

minimize the formation of NOx.

The Rawhide Operating

Permit issued by the State of Colorado limits the NOx emission

rate, which is controlled by the tangentially

fired design of Rawhide's

boiler and the use of an enhanced low-NOx combustion control system.

The tangential boiler design provides improved fuel-air mixing and

combustion staging over other boiler designs, resulting in lower

NOx emissions.

Rawhide's enhanced combustion control (ECC) system utilizes the

latest in boiler burner technology, separated over-fire air registers

and a computerized control system that continuously monitors combustion

variables such as air damper positions, burner tilts, coal feeder

speeds and other process parameters and makes adjustments to keep

NOx emissions

below the permitted rate. The ECC system provides an additional 50%

reduction in NOx emission over the emission rates generally achievable

from the

tangential boiler design.

Click for tangentially fired boiler diagram